Photo: Futurium

Bio-inspired Design

From Pine Cone to Building Facade

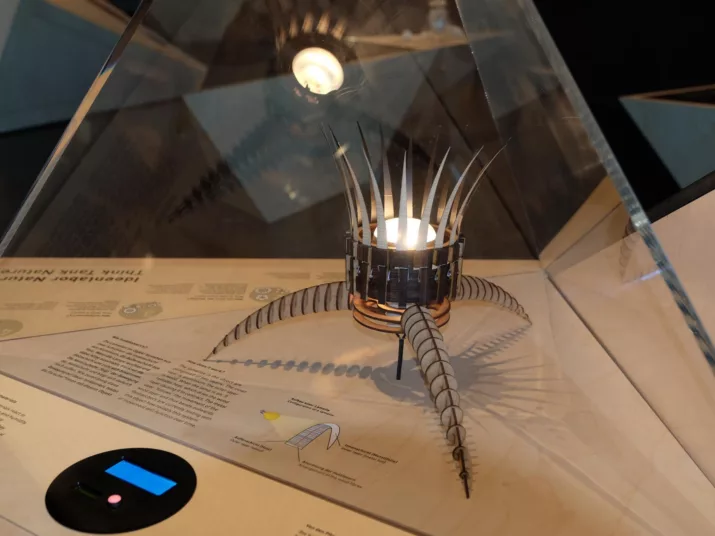

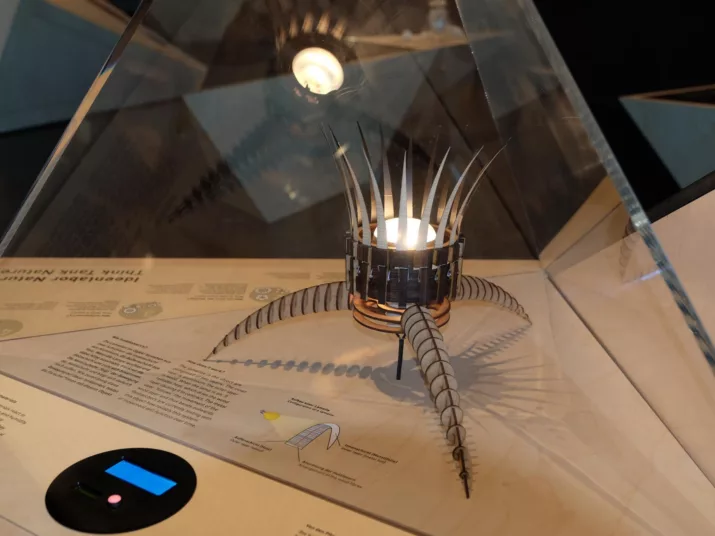

A model displayed at Futurium shows the principle behind the way some plants distribute their seeds: Dr Michaela Eder from the Max Planck Institute of Colloids and Interfaces (MPIKG) explains what lies behind the exhibit “Self-Moving Materials” and how nature can inspire scientists and developers.

Photo: Futurium

Every day we use a great many things – be they smartphones or toothbrushes – and rarely consider what these objects around us are made of. How can nature help in the development of new products?

Michaela Eder: We should thoroughly rethink materials in the future, especially with regard to their use and consumption of resources. For example, it would be exciting if materials were more self-sufficient and could perform simple tasks themselves without having to be controlled by computers and without the use of electrical power. Nature can act as a role model and inspiration. However, the goal is not to copy nature one-to-one, but to pick out certain aspects from a biological model and to put them into practice or develop them further.

In the exhibit “Self-Moving Materials”, which you created for Futurium, slats made of wood and metal start moving at the touch of a button – seemingly by magic. How does it work?

Eder: The exhibit is based on the so-called bilayer principle, which is widespread in nature. The outer layer of the slats is made of thin wood veneer, which bends in a certain direction if the humidity level increases and the material expands. At low humidity levels, the movement is reversed because the wood dries and shrinks. The second, inner layer consists of aluminium. It follows the movement of the wood – and causes the slats in the exhibit to bend. The exhibit was built by Alexandros Ioannou, an architectural student.

How did a native Australian wildflower named banksia come to be the model for this exhibit?

Eder: Actually, the bilayer principle can also be observed in our native pine cones. However, the special feature of our exhibit is that heat is used as an additional trigger. The heat generated by the lamp causes the humidity levels to drop faster. In this way, the movement starts within roughly 90 seconds. Australian banksia needs a certain temperature and humidity for its seedpods to open. They function like small robotic sensors without metabolism, whose functionality is encoded in the material.

I found it fascinating how plants cope with extreme conditions. After all, they can’t run away.

In her research at the Max Planck Institute of Colloids and Interfaces, Dr Michaela Eder focuses on environmental influences on the properties and functions of plant materials.

Photo: privat

How did you come to study banksia?

Eder: I found it fascinating how plants cope with extreme conditions. After all, they can’t run away. They’re firmly rooted in their location. Banksia has adapted to drought, heat and frequent bushfires. For example, we discovered that in the hotter regions of northern Australia the capsules only open at temperatures higher than 70 degrees Celsius – because only when there’s a fire can nutrients be released via the ashes back into the soil. The plant is also triggered by moisture – which is equally important for germination. Another interesting finding was that, in southern Australia, the seedpods of banksia open at merely 50 degrees Celsius – even though it’s the exact same species.

How does the difference arise?

Eder: The curvature of the seedpod is greater in the north than in the south, and this makes the northern specimens more stable. However, we’re not yet sure why they grow differently in different regions. It’s something we’re currently researching.

Even in the exhibit itself, you’re exploring how reliably the movement of the double-layered material is working. What have you observed so far?

Eder: We’re currently taking a closer look at how the exhibit ages, because each day a large number of visitors trigger the movement of the slats by touching the button. Another exciting research questions would be whether there’s a way to reset the system. Does water “repair” the exhibit’s potentially diminishing ability to move?

For ecologists, especially, the question of how vegetation changes when the plant in its home country becomes warmer because of climate change is an interesting one.

What products could be created from this bio-inspired material in the future?

Eder: The principle could be applied in facade elements, among other things. I wish to encourage the visitors to become creative themselves and to think about what they can do with it. Architects and scientists from the University of Stuttgart and ETH Zurich, for example, have demonstrated how architects make use of the “activity” of wood in their designs. They developed and built the 14-metre-tall Urbach Tower in southwest Germany. Its plank plywoods curve autonomously into pre-calculated shapes, without requiring energy-intensive machinery. This is made possible by the layered structure of the wood and a special drying process.

Do you collaborate with other disciplines to research plants with special characteristics like banksia?

Eder: Yes, for example, I work with environmental, wood or material scientists, designers, scholars from the humanities or biologists. For ecologists, especially, the question of how vegetation changes when the plant in its home country becomes warmer because of climate change is an interesting one.

What does your everyday scientific work look like?

Eder: It’s very varied. We’re out in nature a lot, collecting samples and exploring the interactions between plant material and the environment. The samples themselves are mainly examined in the lab, but I also spend a lot of time at my desk evaluating data, studying literature or writing publications. Teamwork is absolutely essential for this.

What do you examine in the lab?

Eder: We examine the structure of the banksia seed capsules under the microscope, for example, or in a computer tomograph. There we heat up the capsules and create 3D images of the opening movements. But we also look at how their mechanical properties change in dry and wet states. All the data and information we obtain help us to understand the system better.